Cost and Value Engineering

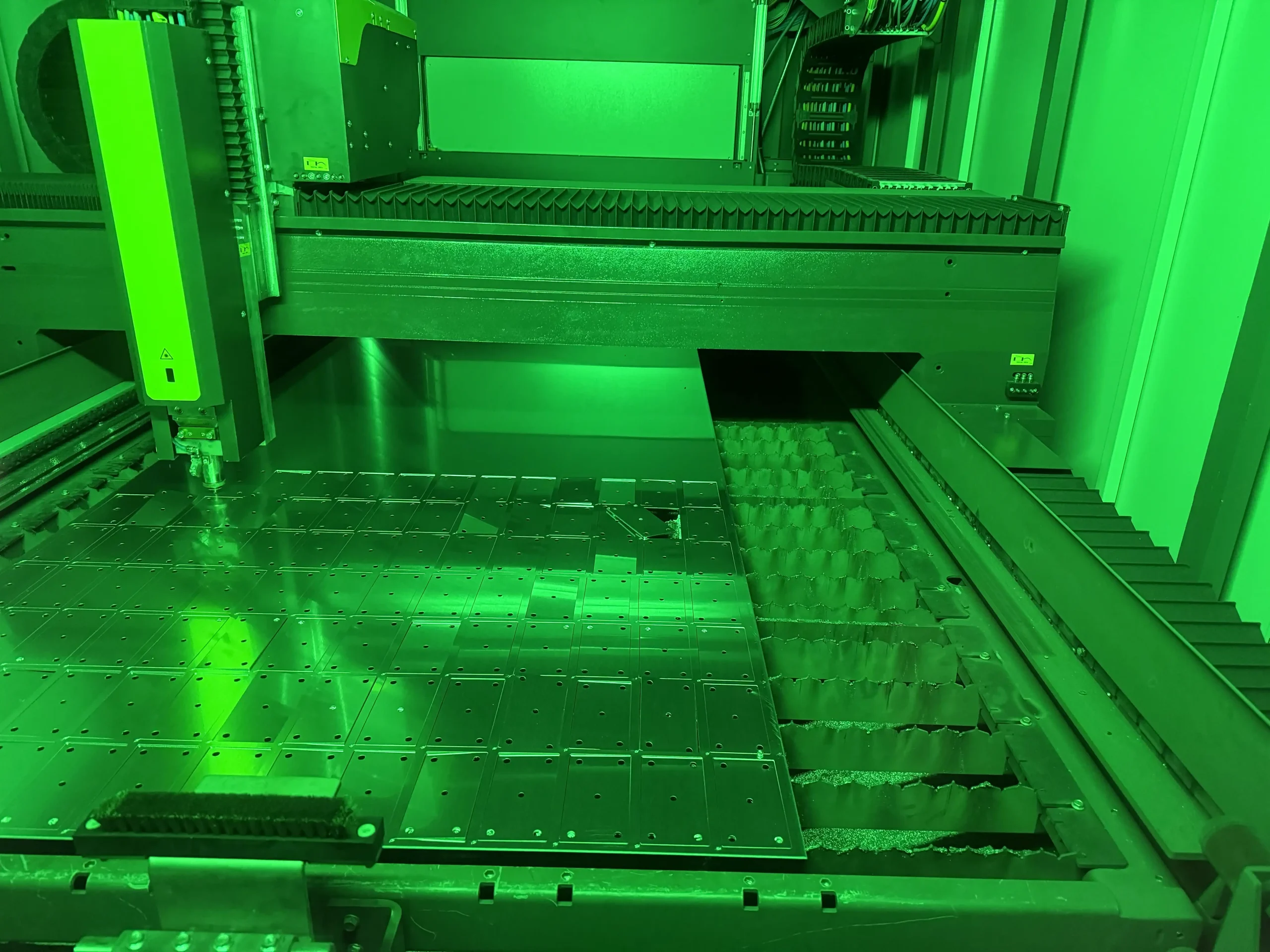

Designed for Manufacture and Value Engineered.

A huge thanks to the brilliant team at T-Rax for constantly supporting a range of our event work! These guys attention to detail and care for each design and product they make for our events is brilliant! Look forward to working with you guys again soon

Cost & Value Engineering

At T-Rax, we believe that good design isn’t just about performance—it’s about delivering maximum value at minimum cost. Our Cost and Value Engineering approach ensures every product we create balances function, quality, and affordability. By analysing materials, processes, and design features, we help you achieve more with less—without compromising on strength, safety, or usability.

What is Cost/Value Engineering?

Cost/Value Engineering (C/VE) is a structured method for improving the value of a product by:

- Reducing unnecessary costs – identifying areas where complexity, over-specification, or inefficient processes add expense.

- Enhancing performance – ensuring the product does its job better, faster, or longer.

- Balancing trade-offs – finding the sweet spot between function, durability, and production efficiency.

In short: it’s about creating products that meet requirements at the lowest lifecycle cost while maximising value for the user.

Why it matters

- Lower production costs – through smarter material selection and simplified fabrication.

- Faster lead times – by eliminating redundant steps in the process.

- Greater competitiveness – more cost-effective products improve your market position.

- Sustainable outcomes – less material waste and energy consumption.

- Longer product life – designs that stand up to repeated use, reducing replacement cycles.

Our approach

1. Function Analysis

We break down the product into its core functions—what must it do, and what features are “nice to have” but add unnecessary cost?

2. Alternative Concepts

We explore alternative materials, geometries, and processes to deliver the same function more efficiently.

3. Value Prioritisation

We collaborate with you to rank functions by importance, ensuring essential features are preserved while cost is minimised.

4. Design Optimisation

CAD models are updated to incorporate simplified features, reduced weld lengths, standard components, and improved access for fabrication.

5. Validation & Testing

We prototype and test to ensure cost savings don’t compromise safety, load ratings, or durability.

Key strategies in Cost/Value Engineering

- Material optimisation – selecting steel grades, sections, or thicknesses that meet performance needs without over-specifying.

- Standardisation – using common components and finishes across products to reduce procurement and stocking costs.

- Process efficiency – reducing welds, simplifying cuts, and minimising finishing steps.

- Design simplification – eliminating non-essential features that add expense but no real value.

- Lifecycle focus – balancing upfront cost with durability, repairability, and ease of recycling.

Industries we support

- Logistics and distribution

- Automotive and engineering

- Construction and utilities

- Retail and warehousing

- Recycling and waste management

Why partner with T-Rax?

- Integrated design and manufacturing – no delays

- UK-based production – faster lead times and tighter quality control

- Custom solutions – every product tailored to your needs

- Full lifecycle support – from design through manufacture to maintenance