Design for Manufacture

Precision Design and Value Engineered Manufacture.

A huge thanks to the brilliant team at T-Rax for constantly supporting a range of our event work! These guys attention to detail and care for each design and product they make for our events is brilliant! Look forward to working with you guys again soon

Design for Manufacture

At T-Rax, we believe great products don’t just need to work—they need to be designed to be made. That’s the principle of Design for Manufacture (DfM): engineering solutions that are practical, efficient and reliable in production, while meeting performance requirements and keeping costs under control.

What is Design for Manufacture?

Design for Manufacture is the process of optimising a product’s design so it can be produced easily, accurately, and at scale. It bridges the gap between concept and reality, considering how materials, tolerances, tooling, and assembly will impact the manufacturing process.

By applying DfM principles from the outset, you can shorten lead times, reduce waste, and eliminate costly redesigns once production begins.

Why DfM matters

- Lower costs: Avoid expensive manufacturing processes by designing for simplicity and efficiency.

- Faster lead times: Streamlined designs reduce machining time, assembly steps, and inspection overhead.

- Improved quality: Designs that match process capability result in fewer defects and better consistency.

- Sustainable outcomes: Less waste and rework contribute to leaner, more environmentally responsible production.

Our approach

1. Early collaboration

We involve our manufacturing experts during the design stage, so feasibility and practicality are built into every iteration.

2. Material and process selection

Choosing the right material isn’t just about strength or appearance—it’s about compatibility with cutting, forming, welding, or coating processes.

3. CAD optimisation

We use advanced CAD tools to model not just the end product, but the steps needed to make it—factoring in machining, bending radius, weld access, and jig design.

4. Prototype & test

Before committing to production, we prototype designs to validate performance and confirm ease of manufacture.

5. Feedback loop

Manufacturing trials and operator input are used to fine-tune the design, ensuring repeatability and efficiency at scale.

Key considerations in DfM

- Tolerances: Designing to what’s needed, not what’s “as tight as possible,” to avoid unnecessary machining and inspection costs.

- Standardisation: Using standard sections, fixings, and finishes reduces procurement complexity.

- Simplicity: Fewer parts, fewer welds, and fewer assembly steps improve reliability.

- Accessibility: Designs that allow easy handling, welding, fastening, and inspection speed up production and reduce defects.

- Scalability: Building in flexibility for future variations without requiring a total redesign.

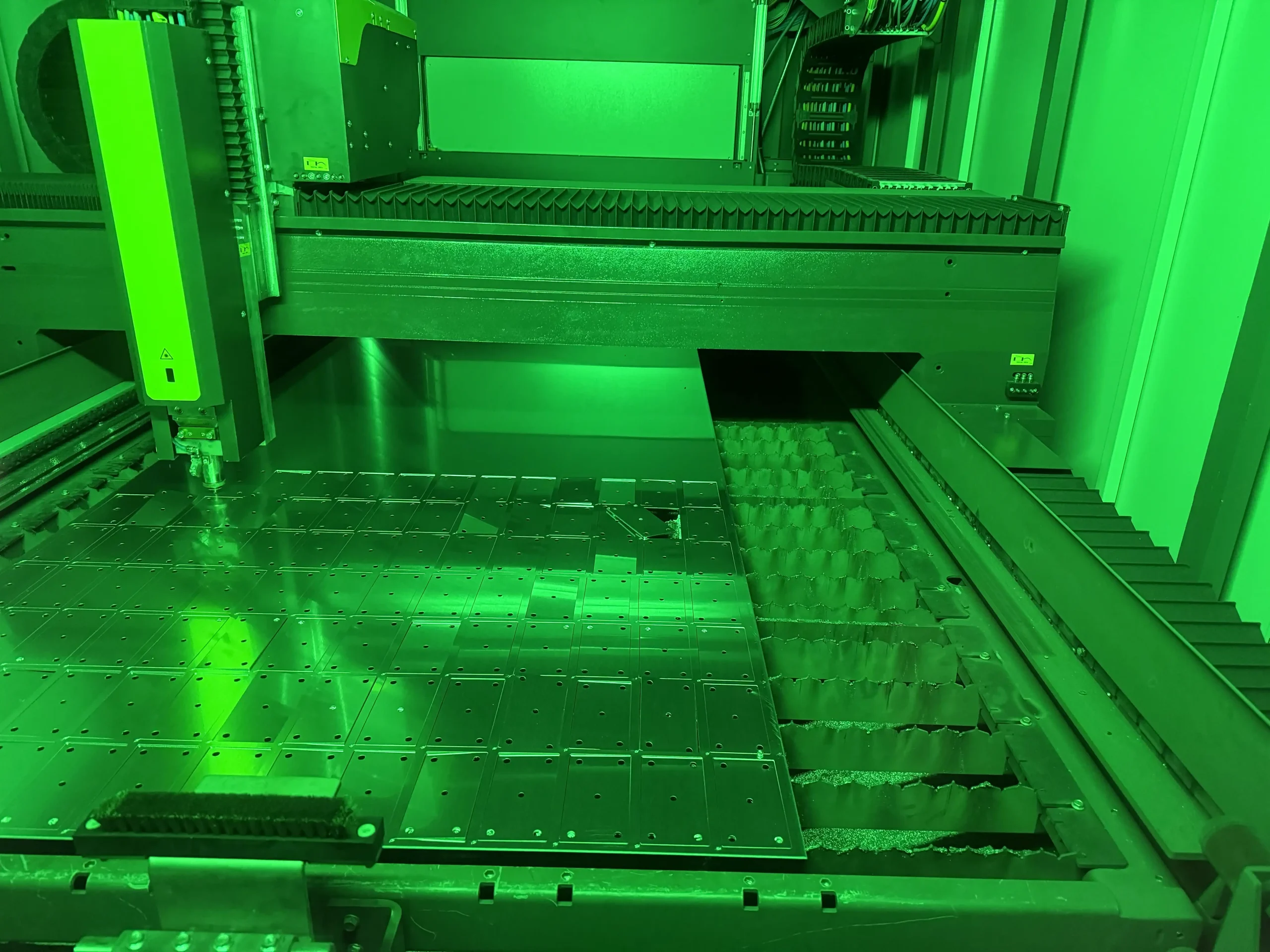

DfM in practice at T-Rax

From heavy-duty stillages and cages to specialist fabrication projects, every design we deliver is evaluated for manufacturability. We balance customer requirements with process capability, ensuring that what looks good on screen can be made cost-effectively on the shop floor—again and again.

Industries we support

- Logistics & material handling

- Manufacturing & engineering

- Construction & utilities

- Automotive & transport

- Retail & warehousing