Galvanising

Protective, long-lasting galvanised coating for steel.

Turnkey Fabrication Service

Fully Customisable Design

Fast Turnaround

Personalised Service

A huge thanks to the brilliant team at T-Rax for constantly supporting a range of our event work! These guys attention to detail and care for each design and product they make for our events is brilliant! Look forward to working with you guys again soon

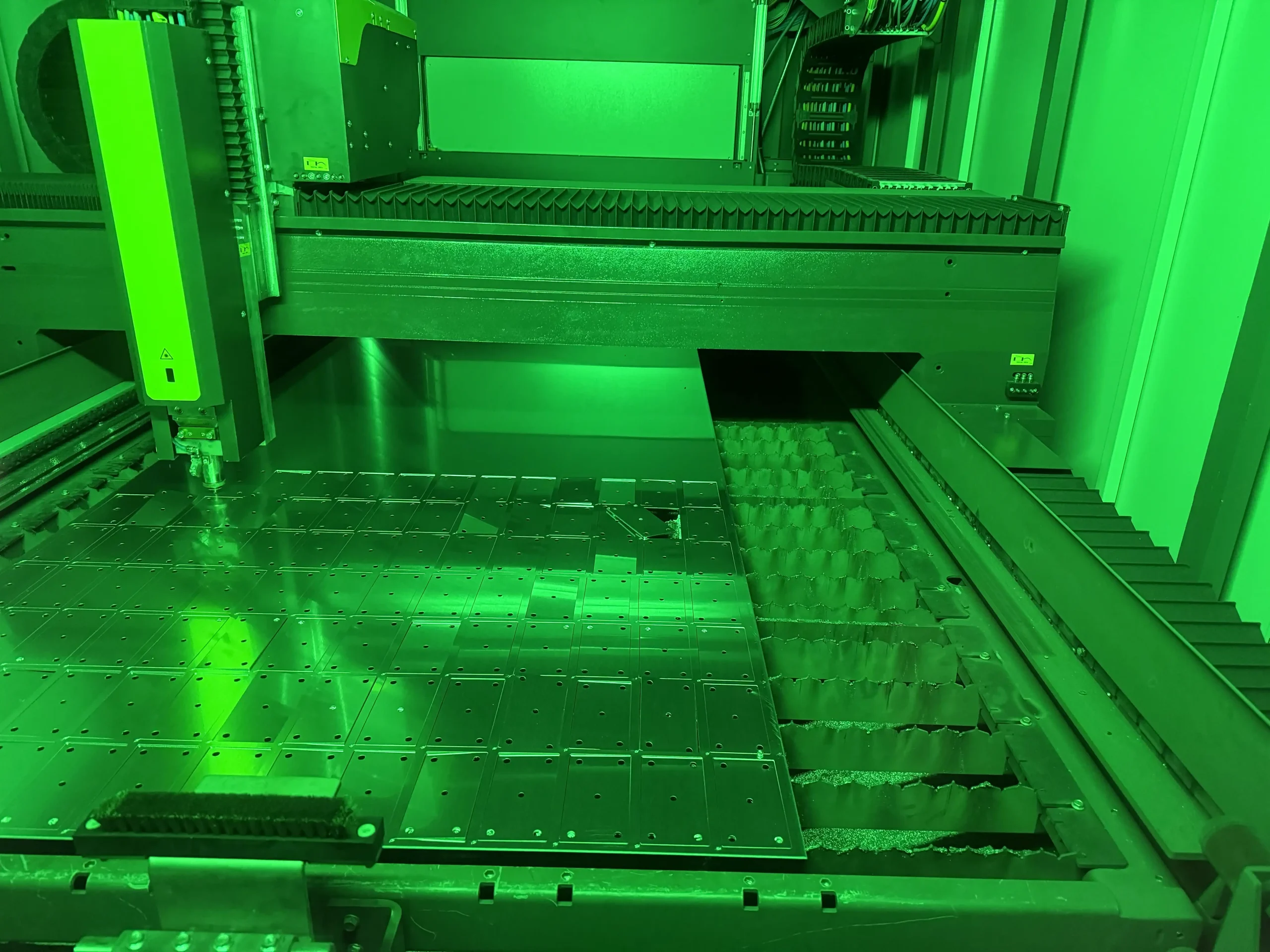

Galvanising at T-Rax

At T-Rax, our galvanising service is built on precision, durability, and long-term protection. Whether you’re after a single galvanized part or a large batch, we deliver UK-based galvanic finishing tailored to your project’s demands.

What We Do – Galvanising at T-Rax

Our galvanising process typically includes:

- Surface Preparation & Cleaning – Degreasing, pickling, and fluxing to remove oil, scale, rust, and residues so that the zinc bonds properly

- Immersion in Molten Zinc – Hot-dip galvanising in temperature-controlled zinc baths for full coverage

- Post-Treatment & Passivation – Quenching, possible passivation or sealing to improve appearance, reduce white rust and enhance adhesion

- Inspection & Quality Assurance – Checking coating thickness, adhesion, uniformity, and visual finish

What You’ll Get with T-Rax Galvanising

- Superior Corrosion Protection — Ideal for exterior, marine, or industrial settings; zinc sacrificially protects steel

- Even, Complete Coating — Coverage even in recessed or hard-to-reach areas

- Long Life & Low Maintenance — Reduces need for re-coating, meaning lower lifetime cost

- Industry Compliance & Standards — Coatings meeting BS EN ISO 1461 (or other relevant standards)

- Scalable Service — From one-off pieces to industrial batches

- Local, Reliable Expertise — All work done in our UK facility under close supervision

Why Choose Galvanising Over Powder Coating (or Vice Versa)?

- Galvanising provides deep corrosion resistance, especially for outdoor or harsh environments.

- Powder coating offers customisable finishes in aesthetic colours and textures.

- Many customers combine both: first galvanising for metal protection, then powder coating for aesthetics (i.e. galvanise for corrosion resistance, then top coat for colour).

- We can advise which route—or combination—is best for your project, material, environment, and budget.