Stillage Design an Manufacture

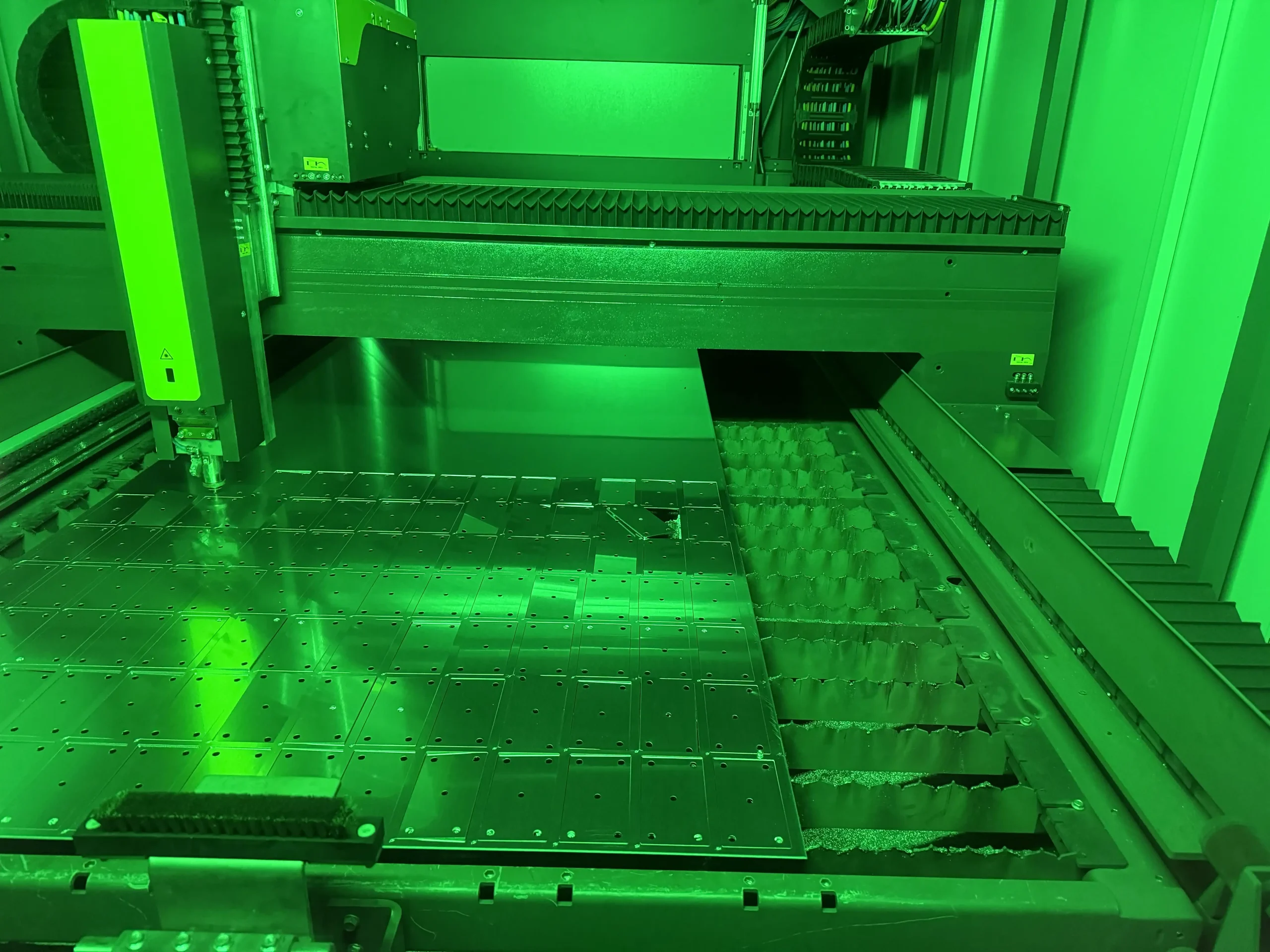

Precision Design and Repeatable Manufacture.

A huge thanks to the brilliant team at T-Rax for constantly supporting a range of our event work! These guys attention to detail and care for each design and product they make for our events is brilliant! Look forward to working with you guys again soon

Stillage Design & Manufacture

T-Rax designs and manufactures heavy-duty steel stillages and parcel/retention cages that make handling, storage and transport safer, faster and more efficient. From a single prototype to a full production run, we build to your specification and environment—warehouse, factory, logistics hub, construction site and beyond.

Why choose a stillage?

A stillage is a robust, often stackable steel container or palletised frame that protects goods in storage and transit, improves space utilisation and speeds up loading/unloading. Common formats include mesh-sided cages, solid-sided bins and post pallets; they can be rigid, folding or nesting to save space when empty.

Key benefits

- Safer handling: defined load areas, fork pockets/crane points and secure sides minimise damage and injury risk.

- Higher density storage: stackable designs and pallet footprints maximise racking and floor space.

- Faster operations: easy access doors/gates and standardised footprints keep goods moving.

Our design & build process

- Discovery & brief – We capture what you’re storing, how it’s moved, stack heights, MHE interfaces (forklift, crane, tug), and any compliance constraints.

- CAD engineering – We produce 3D models for review, iterate fast on detail (mesh pitch, base, posts, gates), and lock down a tested, costed design prior to fabrication.

- Manufacture – Precision-fabricated in steel with quality welds, jigs for repeatability, and options for powder-coated or galvanised finishes suited to your environment.

- Inspection & sign-off – Functional checks, stack trials and dimensional verification before delivery.

- Repeatable supply – Consistent batches, spares and repair service to extend lifecycle.

Popular stillage & cage types we build

- Mesh parcel/retention cages – For parcels, 3PL, postal and retail distribution. Options include half-drop/hinged gates, shelves, ID plates and card holders.

- Solid-sided stillages/bins – For swarf, pressings, castings and loose components; prevents fines escaping and improves housekeeping.

- Post pallets (demountable/stackable) – Simple, bomb-proof frames for uniform loads and long goods; posts maintain stack alignment.

- A-frame/“A” stillages – Ideal for sheet, glass and slab products.

- Tyre stillages – Space-efficient racking for high tyre volumes in distribution and retail.

- Extrusion/long-load stillages – For aluminium/plastic extrusions, pipe and conduit; protects surfaces and controls deflection.

- IBC & drum stillages – For liquid containers; with fork-pocket access points and robust bases.

Options & finishes

- Access: half-drop or full-height gates, removable sides, hinged or sliding doors.

- Space saving: folding/nesting versions to cut backhaul and empty storage costs.

- Floor/base: sheeted, open, timber-decked, anti-spill, stillage feet or pallet runners.

- Handling features: fork pockets, crane lugs/eyes (as specified), push-pull bars, tow hitches.

- Identification: welded nameplates, card holders, serial/QR plates, colour-coded batches.

- Finishes: hard-wearing powder-coat for indoor/retail; galvanised options for outdoor/heavy-duty use.

Industries we support

Parcel & postal networks, 3PL/fulfilment, automotive, manufacturing/engineering, building products, utilities, retail back-of-house and recycling/waste management—wherever there’s a load to protect and move efficiently.

What to expect from T-Rax

- Bespoke engineering, not one-size-fits-all: every stillage is built for your product, process and equipment.

- UK design and manufacture: responsive lead times and easier quality assurance.

- End-to-end service: concept, CAD, prototyping, production, finishing and delivery—plus repeat runs as you scale.

FAQs

What’s the difference between a cage and a stillage?

“Cage” tends to mean a mesh-sided stillage that offers visibility and ventilation; “stillage” is the wider family that also includes solid-sided bins, post pallets and frames. Both are engineered for stacking and safe MHE handling.

Can you make folding or nesting versions to save space?

Yes—folding and nesting options reduce cube when empty and cut return-leg costs.

Can you supply finishes to suit harsh or retail environments?

We offer durable powder-coated finishes for indoor use and galvanised options for outdoor or corrosive settings.

Do you work to a specific load rating?

We design to your required safe working load and stack configuration, validating the specification during CAD/prototyping and final inspection.